Industrial Architecture Services

Manufacturing Facilities

Manufacturing buildings must support production processes efficiently while accommodating specialized equipment, workflow, and future flexibility:

Manufacturing Design Expertise:

Production floor layout and workflow optimization

Heavy equipment foundations and floor loading capacity

Overhead crane systems and clear heights

Process utility requirements (power, compressed air, water, drainage)

Material receiving and shipping logistics

Office and support space integration

Future expansion accommodation

We begin every manufacturing project by understanding your production process. How do materials flow through your facility? What equipment needs to be accommodated? What utility services are required? Where are bottlenecks in your current operation? This operational understanding drives building design.

Manufacturing Building Types:

Light manufacturing and assembly

Food processing and beverage production

Metal fabrication and machine shops

Electronics and precision manufacturing

Aerospace and defense industry facilities

Pharmaceutical and medical device manufacturing

Jacksonville's industrial market includes diverse manufacturing operations, from aerospace companies at Cecil Commerce Center to food processing facilities throughout the region. Each industry has specific requirements—floor flatness tolerances, contamination control, regulatory compliance, specialized systems—that we incorporate into design.

Warehouse & Distribution Centers

E-commerce growth and supply chain optimization drive demand for efficient warehouse and distribution space:

Warehouse Design Specialization:

Clear height optimization (24'-36'+ clear is standard)

Dock door quantity and spacing

Trailer parking and circulation

Racking layout and aisle widths

Order picking vs. bulk storage configurations

Cross-dock vs. traditional warehousing

Automated material handling systems

Modern warehouses are sophisticated logistics operations. We design for efficiency: minimizing travel distances, optimizing dock utilization, accommodating racking systems, and planning for future automation. Details matter—dock leveler types, door seal systems, floor flatness specifications, lighting levels—all impact operational efficiency.

Warehouse Types:

Regional distribution centers

Last-mile delivery facilities

Cold storage and refrigerated warehouses

Third-party logistics (3PL) facilities

E-commerce fulfillment centers

Bulk storage warehouses

Jacksonville's strategic location—interstate highway access, port facilities, rail connections, and central position on Florida's east coast—makes it an attractive warehouse and distribution location. We understand site selection criteria and design buildings supporting logistics operations.

Flex Space & Light Industrial

Flex buildings combine warehouse, manufacturing, and office space in adaptable configurations:

Flex Space Features:

15-25% office, 75-85% warehouse/manufacturing

Drive-in doors and dock doors

Moderate clear heights (18'-24')

Flexible unit sizes for multi-tenant buildings

Mezzanine potential for additional office or storage

Utility infrastructure supporting varied uses

Flex space serves small manufacturers, distributors, contractors, and service businesses needing combined workspace. These buildings work well for speculative development—developers can lease to diverse tenants without knowing specific uses upfront.

Flex Space Applications:

Contractor offices and storage

Small manufacturer production and admin offices

Parts distribution and sales offices

Research and development facilities

Showroom and warehouse combinations

Industrial Build-to-Suit Projects

Build-to-suit industrial projects are custom-designed for specific tenant needs:

Build-to-Suit Process:

Long-term lease or build-for-sale structure

Custom design meeting tenant's exact requirements

Site selection supporting operations

Specialized systems and infrastructure

Tenant approval at key design milestones

Pre-leased before construction completion

Build-to-suit projects benefit both tenants (getting exactly what they need) and developers/owners (having committed tenants before construction). We coordinate closely with all parties, balancing tenant requirements with owner's development constraints and future flexibility.

Industrial Tenant Improvements

Many industrial tenants lease existing buildings requiring modifications:

Tenant Improvement Services:

Space planning and layout design

Office build-out and finishes

Dock door additions or modifications

Mezzanine additions for offices or storage

Utility upgrades (power, HVAC, lighting)

Specialized equipment accommodation

Code compliance and permitting

Tenant improvement work requires understanding both the existing building's constraints and the tenant's operational needs. We assess existing conditions, develop improvement plans, and coordinate with landlords to implement necessary modifications.

Speculative Industrial Buildings

Developers building industrial space without pre-committed tenants need flexible, marketable designs:

Speculative Industrial Design:

Standard building dimensions and clear heights

Efficient truck courts and dock door spacing

Divisible for multiple tenants

Core-and-shell vs. fully-finished options

Market-appropriate features and finishes

Cost-effective construction

Speculative industrial buildings must appeal to the broadest tenant base. We design buildings that are functional for most industrial uses while maintaining construction cost discipline. These buildings compete on functionality, location, and lease rates.

Specialized Industrial Facilities

Some industrial operations require unique facilities:

Cold Storage & Refrigerated Warehouses:

Insulated building envelopes and freezer construction

Refrigeration systems and cold storage design

Loading dock vestibules and temperature control

Floor heating to prevent freeze heave

Food-grade finishes and USDA/FDA compliance

Data Centers:

Redundant power and cooling systems

Security and access control

Raised floor systems

Precision environmental control

Future capacity and scalability

Automotive & Heavy Equipment Facilities:

High bay clearances for large equipment

Heavy-duty floors for vehicle loading

Service bay layouts and equipment lifts

Parts storage and inventory management

Customer areas and administrative offices

Aviation & Aerospace Facilities:

Hangar door systems and aircraft clearances

Apron and taxiway coordination

Specialized equipment and clean room requirements

Security and restricted area compliance

Our Industrial Design Process

Phase 1: Programming & Feasibility (2-3 weeks)

Industrial projects begin with understanding operational requirements and development feasibility:

Operational Programming:

Current and future space requirements

Workflow and process analysis

Equipment requirements and specifications

Utility needs (power, water, gas, compressed air, process utilities)

Staffing and parking requirements

Storage and inventory needs

Shipping and receiving volume

Site Evaluation:

Zoning compliance (industrial districts, permitted uses)

Site size accommodating building and truck circulation

Utility availability and capacity

Soil conditions and foundation requirements

Drainage and stormwater management

Access and truck routing

Environmental considerations

Feasibility Analysis:

Building program confirming site can accommodate requirements

Preliminary budget estimates

Construction timeline projections

Permitting requirements and timeline

Utility extension costs

This upfront analysis prevents investing in design for unbuildable or unfeasible projects.

Phase 2: Schematic Design (3-4 weeks)

Schematic design establishes the building's basic layout:

Site Planning:

Building placement optimizing truck circulation

Dock door orientation and truck court layout

Employee and visitor parking

Future expansion areas

Stormwater management and landscaping

Building Design:

Building footprint and dimensions

Clear heights and structural system

Dock door and drive-in door locations

Office area size and location

Restrooms, break rooms, and support spaces

Mezzanine areas (if applicable)

Structural System Selection:

Pre-engineered metal building (PEMB) vs. conventional steel

Column spacing and bay sizes

Roof system and drainage

Foundation system

Schematic design drawings show basic floor plans, elevations, and site layouts. Cost estimating at this stage provides budget validation.

Phase 3: Design Development (4-6 weeks)

Design development refines and coordinates all building systems:

Architectural Refinement:

Finalized floor plans with dimensions

Door and window schedules

Material selections (wall panels, roofing, doors, windows)

Office and support space layouts

Interior finishes

Structural Engineering:

Detailed structural framing plans

Foundation design

Roof structure and loading

Crane system engineering (if required)

MEP Engineering Coordination:

Electrical service size and distribution

Lighting design and controls

HVAC systems and zoning

Plumbing fixtures and drainage

Fire protection systems

Code Compliance:

Building code analysis (occupancy type, construction type)

Fire protection requirements

Accessibility compliance

Energy code compliance

Design development produces a coordinated package ready for detailed construction documentation.

Phase 4: Construction Documents (6-10 weeks)

Construction documents are the detailed plans for building the project:

Architectural plans (typically 15-30 sheets)

Structural engineering drawings

MEP engineering drawings

Civil engineering (site work, grading, utilities)

Specifications detailing materials and installation

Door, window, and finish schedules

Industrial construction documents emphasize clarity and coordination. Well-documented projects minimize contractor questions, reduce change orders, and ensure efficient construction.

Phase 5: Permitting (4-8 weeks)

Industrial permits require multiple agency approvals:

Building Permits:

City or county building department approval

Plan review for code compliance

Fire marshal review

Health department (for food processing or specialized uses)

Site Development Permits:

Site work and grading permits

Stormwater management approvals

Utility connection permits

Driveway and access permits

Environmental Permits (if applicable):

Wetlands and environmental resource permits

Air quality permits (for certain manufacturing)

Wastewater discharge permits

Jacksonville-area industrial permitting typically takes 4-8 weeks for straightforward projects. We coordinate all submittals and respond to review comments, keeping projects moving toward approval.

Phase 6: Construction Administration (duration varies)

During construction, we support the owner and contractor:

Pre-construction meetings reviewing constructability

Site observation visits documenting progress

Reviewing contractor RFIs and shop drawings

Verifying materials match specifications

Monitoring construction quality

Developing punch lists

Supporting Certificate of Occupancy approval

Industrial construction moves quickly—typical projects complete in 6-12 months depending on size and complexity. Our involvement ensures quality execution and protects owner interests.

Why Industrial Clients Choose ZINN

See why clients trust ZINN Architecture for their projects.

Cost-Effective Design

Industrial clients need maximum value, not architectural statements. We design efficiently:

Cost Optimization Strategies:

Simple, efficient building forms

Repetitive structural bays

Standard materials and systems

Pre-engineered metal buildings where appropriate

Minimizing unnecessary finishes

Value engineering throughout design

Industrial buildings should be cost-effective to build and inexpensive to operate. We don't over-design or add unnecessary complexity. Every design decision considers both initial cost and life-cycle costs.

Operational Efficiency Focus

Buildings support business operations—we design for efficiency:

Layouts minimizing material handling and travel distances

Adequate space for equipment maintenance and circulation

Proper environmental conditions for processes and employees

Utility infrastructure supporting operations

Future flexibility for changing needs

We think like operators, not just designers. How will forklifts circulate? Where do employees enter? How are materials received and shipped? These operational details drive design.

Speed to Completion

Time is money in industrial development. Delays cost carrying costs, lost revenue, and missed market opportunities. We move projects efficiently:

Streamlined design processes

Fast-track design and permitting where possible

Pre-engineered building systems accelerating construction

Responsive to contractor questions during construction

Coordination preventing delays

Our experience helps anticipate issues, prevent problems, and keep projects on schedule.

Northeast Florida Industrial Market Knowledge

We understand Jacksonville's industrial market and sites:

Key Industrial Locations:

Cecil Commerce Center: Former naval air station, large sites, aviation/aerospace focus

I-95 Corridor: Distribution and logistics, highway access

Deerwood/Southside: Flex space, light industrial, proximity to workforce

Westside Industrial: Traditional manufacturing and warehouse area

Oceanport/Blount Island: Port-related industrial, heavy industrial

Northside: Warehouse and distribution, affordable land

Site selection impacts operations, workforce access, and development costs. We advise on location considerations and design buildings optimized for specific sites.

Regulatory Compliance & Permitting

Industrial projects face extensive regulations:

Industrial zoning compliance

Building codes for factory-industrial occupancies

Fire protection and life safety requirements

Environmental regulations (air quality, stormwater, hazardous materials)

Accessibility requirements

Energy code compliance

We navigate these regulations routinely, understanding how they impact design and what's required for permit approval. Our relationships with local building officials help projects move smoothly through approvals.

Industrial Project Economics

Construction Costs

Northeast Florida industrial construction costs (2025):

Basic Warehouse/Distribution:

Pre-engineered metal building, shell: $60-$80 per SF

With office build-out and finishes: $80-$100 per SF

Standard Industrial/Manufacturing:

Pre-engineered or steel frame: $90-$130 per SF

Includes basic office, utilities, finishes

Heavy Manufacturing:

Heavy-duty floors, crane systems, specialized equipment: $130-$180+ per SF

Flex Space:

Multi-tenant buildings with mixed office/warehouse: $100-$140 per SF

Cold Storage/Specialized:

Refrigerated warehouses, clean rooms, specialized facilities: $180-$250+ per SF

These costs include site work, building, utilities, parking, and landscaping. Costs vary based on site conditions, building specifications, and market conditions.

Architectural & Engineering Fees

Industrial A&E fees typically range from 3-6% of construction costs:

Example Projects:

50,000 SF warehouse ($4M construction): $120K-$240K A&E fees

30,000 SF manufacturing facility ($3.5M construction): $105K-$210K A&E fees

100,000 SF distribution center ($8M construction): $240K-$480K A&E fees

Fees cover architecture, structural engineering, MEP engineering, civil engineering, and construction administration. Complex projects requiring specialized engineering or fast-track schedules may have higher fees.

Development Timelines

Small to Medium Industrial (20,000-50,000 SF):

Design: 3-5 months

Permitting: 2-3 months

Construction: 6-10 months

Total: 11-18 months

Large Industrial/Distribution (50,000-200,000 SF):

Design: 4-6 months

Permitting: 3-4 months

Construction: 10-16 months

Total: 17-26 months

Complex Manufacturing:

Design: 5-8 months

Permitting: 3-6 months

Construction: 12-20 months

Total: 20-34 months

Fast-track approaches can compress schedules by overlapping design, permitting, and construction phases.

Frequently Asked Questions

What's the difference between a pre-engineered metal building and conventional steel construction?

Pre-engineered metal buildings (PEMBs) use standardized components fabricated off-site and erected quickly. They're cost-effective for simple rectangular buildings with standard features. Conventional steel construction offers more flexibility for complex shapes, heavy loading, or specialized requirements. We evaluate which approach best serves your project's needs and budget.

How do you optimize warehouse clear height?

Clear height impacts storage capacity and operational efficiency. We evaluate the tradeoff between higher clear heights (more vertical storage) and increased building cost. Site conditions also matter—poor soils may require expensive foundations for taller buildings. We model different height scenarios showing storage capacity gains versus cost increases.

Can you design for future expansion?

Yes. We plan for future expansion by positioning the building on site to allow additions, designing structural systems that can extend, and providing utility infrastructure with excess capacity. Initial investment in expansion planning pays off when growth happens—you'll add to your facility rather than relocating.

How long does industrial construction take?

Construction duration depends on building size and complexity. Simple pre-engineered warehouses can complete in 6-8 months. Complex manufacturing facilities requiring specialized systems may take 12-20 months. We provide realistic timelines based on specific project parameters.

What energy efficiency features make sense for industrial buildings?

High-efficiency lighting (LED with occupancy sensors) offers quick payback. Insulated roof and wall panels reduce heating/cooling costs. Natural lighting through skylights or translucent panels reduces lighting energy. HVAC system efficiency matters, particularly in climate-controlled spaces. We evaluate energy measures based on cost vs. savings payback.

Do you help with site selection?

Yes. We can evaluate potential sites for suitability—assessing whether sites accommodate your building and operational needs, reviewing zoning compliance, identifying utility concerns, and estimating site development costs. Early-stage site due diligence prevents costly surprises.

How do you control construction costs?

We provide cost estimates at each design phase and continuously monitor budgets. Value engineering identifies cost-saving opportunities without compromising functionality. Construction document clarity reduces contractor contingencies and change orders. Early contractor involvement (design-build or construction manager approaches) can also improve cost control.

What building codes apply to industrial projects?

Industrial buildings typically fall under factory-industrial occupancy classifications in the Florida Building Code. Requirements cover fire protection, means of egress, structural design, accessibility, and energy efficiency. Specialized uses (food processing, hazardous materials, etc.) have additional requirements. We ensure designs comply with all applicable codes.

Can you work with design-build contractors?

Absolutely. We regularly participate in design-build projects, either as the architect partnering with a contractor or joining the owner's team to review design-build proposals. Design-build can accelerate schedules and improve cost control when structured properly.

Do you design outside Jacksonville?

Yes. While we have extensive Northeast Florida experience, we've completed industrial projects throughout Florida and beyond. Our industrial expertise translates across locations, though we coordinate with local civil engineers and consultants familiar with specific jurisdictions.

Ready to Discuss Your Industrial Project?

Whether you're planning a new manufacturing facility, need warehouse space, or require tenant improvements to existing industrial buildings, ZINN brings proven industrial architecture expertise and practical, cost-effective solutions.

Contact us today to discuss your project requirements. We'll evaluate your needs, review potential sites or existing facilities, and outline how we can help you achieve your industrial facility goals.

Tell Us About Your Project | Call: 904.352.1203

Related Services

Commercial Architecture - Retail, office, and mixed-use projects

Multi-Family Design - Apartments and townhomes

Residential Architecture - Custom homes and renovations

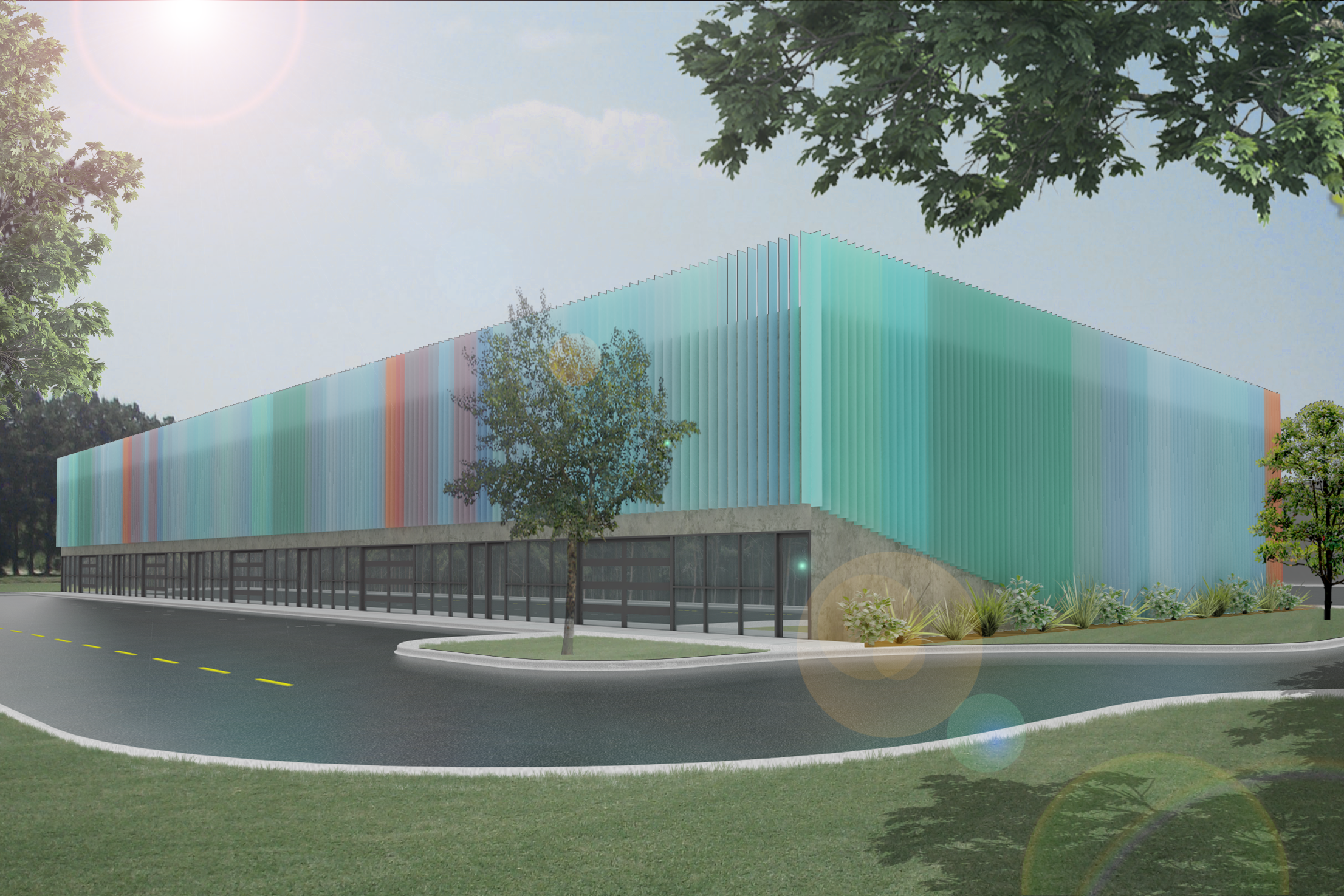

Industrial Architecture: Efficiency & Precision

Northeast Florida's Industrial Architecture Specialists

At ZINN, we bring over 30 years of industrial architecture experience and more than 1 million square feet of completed industrial projects in Northeast Florida alone. We understand that industrial architecture succeeds when buildings operate efficiently, construction stays on budget and schedule, and facilities support your business operations for decades to come.

Industrial projects demand a different approach than residential or commercial work. There's less emphasis on aesthetics and more focus on functionality, efficiency, and cost-effectiveness. Your industrial building is a tool for your business—it needs to work hard, work reliably, and deliver value over its useful life.

Whether you're a manufacturer needing a new production facility, a logistics company requiring distribution space, a developer building speculative industrial buildings, or a business expanding your existing operations, ZINN delivers industrial architecture that performs.